Browse Categories

Metric Pitch

Polyurethane Endless Construction

Steel or (K) Kevlar Cords

PDF - Belts-Timing-MetricPitch.pdf

Technical Specifications

PDF - Timing Belts PU T5 Technical Spes.pdf

Subcategories below:

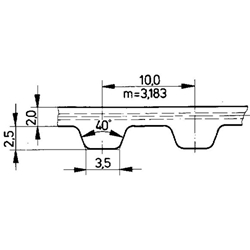

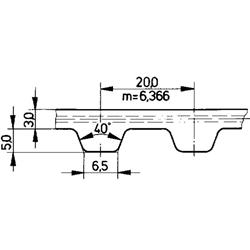

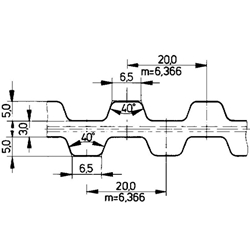

Timing Belt Polyurethane T2.5, T5, T10, T20, AT5, AT10 & D

PU timing belts are suitable for high power and precision motion control, even at high speeds. Our belts perform especially well on light synchronized and stepped drives, in office automation and domestic appliance applications.

Polyester, Kevlar® (Aramid) and steel cord available.

Yellow, grey, red, transparent colors available.

PU Truly Endless timing belts are manufactured by a unique thermoset molding process. The high-grade polyurethane gives excellent abrasion and shear resistance, combined with a variety of graded steel cords, ensuring high strength and tractive resistance. The result is a timing belt with excellent dimensional stability. Ametric® Transmission mounded timing belts are manufactured to a tight tolerance range, which assures consistent length and thickness. The combination of these factors results in Ametric® transmission belts performing to the highest physical and chemical levels.

Features:

- High flexibility;

- Small pulley diameters;

- Dimensional accuracy;

- High speed;

- Energy efficient;

- Low noise and vibration;

- Low maintenance;

- Good chemical and ozone resistance;

- High friction surface.

Pouring polyester polyurethane plastics technology

|

Item \ unified labeling |

A6 |

A7 |

A8 |

A9 |

|

Hardness |

65 ± 5 |

75 ± 5 |

85 ± 5 |

> 90 |

|

strength (KG/cm²) |

> 30 |

> 50 |

> 70 |

> 120 |

|

Tensile strength (KG/cm²) |

> 250 |

> 350 |

> 400 |

> 450 |

|

Elongation at break (%) |

> 500 |

> 450 |

> 450 |

> 450 |

|

Permanent deformation(%) |

< 15 |

< 15 |

x < 15 |

< 15 |

|

Tear strength (KG/cm²) |

> 30 |

> 45 |

> 75 |

> 90 |

|

Impact Rebound (%) |

> 15 |

> 15 |

> 15 |

> 15 |

|

Brittle temperature(ºC) |

< -50 |

< -50 |

< -50 |

< -50 |

|

Wear (Cm³/1.6KM) |

< 0.05 |

< 0.05 |

< 0.05 |

< 0.05 |

|

Aging coefficient(100ºCX24Hour) |

> 0.9 |

> 0.9 |

> 0.9 |

> 0.9 |

|

Water resistance coefficient(70ºCX24Hour) |

> 0.8 |

> 0.8 |

> 0.8 |

> 0.8 |

|

Resistance No. 120 petrol + benzene(15~25ºCX24 hours) |

< +0.2 |

< +0.2 |

< +0.2 |

< +0.2 |

|

Resistance on the 20th oil(700ºC X ± 2ºC X 24 hours) |

< +0.4 |

< +0.4 |

< +0.4 |

< +0.4 |

- 3A252.10

- 3A252.100

- 3A252.11

- 3A252.12

- 3A252.14

- 3A252.16

- 3A252.20

- 3A252.25

- 3A252.32

- 3A252.50

- 3A252.6

- 3A252.60

- 3A252.7

- 3A252.75

- 3A252.8

- 3A267.10

- 3A267.100

- 3A267.11

- 3A267.12

- 3A267.14

- 3A267.16

- 3A267.20

- 3A267.25

- 3A267.32

- 3A267.50

- 3A267.6

- 3A267.60

- 3A267.7

- 3A267.75

- 3A267.8

- 3A351.50

- 3A600.10

- 3A600.100

- 3A600.11

- 3A600.12

- 3A600.14

- 3A600.16

- 3A600.20

- 3A600.25

- 3A600.32

- 3A600.50

- 3A600.6

- 3A600.60

- 3A600.7

- 3A600.75

- 3A600.8

- 3A816.10

- 5A1050.10

- 5A1050.100

- 5A1050.11

- 5A1050.12

- 5A1050.14

- 5A1050.16

- 5A1050.20

- 5A1050.25

- 5A1050.32

- 5A1050.50

- 5A1050.6

- 5A1050.60

- 5A1050.7

- 5A1050.75

- 5A1050.8

- 5A1125.10

- 5A1125.100

- 5A1125.11

- 5A1125.12

- 5A1125.14

- 5A1125.16

- 5A1125.20

- 5A1125.25

- 5A1125.32

- 5A1125.50

- 5A1125.6

- 5A1125.60

- 5A1125.7

- 5A1125.75

- 5A1125.8

- 5A1500.10

- 5A1500.100

- 5A1500.11

- 5A1500.12

- 5A1500.14

- 5A1500.16

- 5A1500.20

- 5A1500.25

- 5A1500.32

- 5A1500.50

- 5A1500.6

- 5A1500.60

- 5A1500.7

- 5A1500.75

- 5A1500.8

- 5A1750.10

- 5A1750.100

- 5A1750.11

- 5A1750.12

- 5A1750.14

- 5A1750.16

- 5A1750.20

- 5A1750.25

- 5A1750.32

- 5A1750.50

- 5A1750.6

- 5A1750.60

- 5A1750.7

- 5A1750.75

- 5A1750.8

- 5A2000.10

- 5A2000.100

- 5A2000.11

- 5A2000.12

- 5A2000.14

- 5A2000.16

- 5A2000.20

- 5A2000.25

- 5A2000.32

- 5A2000.4.5

- 5A2000.50

- 5A2000.6

- 5A2000.60

- 5A2000.7

- 5A2000.75

- 5A2000.8

- 5A225.10

- 5A225.100

- 5A225.11

- 5A225.12

- 5A225.14

- 5A225.16

- 5A225.20

- 5A225.25

- 5A225.32

- 5A225.50

- 5A225.6

- 5A225.60

- 5A225.7

- 5A225.75

- 5A225.8

- 5A255.10

- 5A255.100

- 5A255.11

- 5A255.12

- 5A255.14

- 5A255.16

- 5A255.20

- 5A255.25

- 5A255.32

- 5A255.50

- 5A255.6

- 5A255.60

- 5A255.7

- 5A255.75

- 5A255.8

- 5A260.10

- 5A260.100

- 5A260.11

- 5A260.12

- 5A260.14

- 5A260.16

- 5A260.20

- 5A260.25

- 5A260.32

- 5A260.50

- 5A260.6

- 5A260.60

- 5A260.7

- 5A260.75

- 5A260.8

- 5A280.10

- 5A280.100

- 5A280.11

- 5A280.12

- 5A280.14

- 5A280.16

- 5A280.20

- 5A280.25

- 5A280.32

- 5A280.50

- 5A280.6

- 5A280.60

- 5A280.7

- 5A280.75

- 5A280.8

- 5A300.10

- 5A300.100

- 5A300.11

- 5A300.12

- 5A300.14

- 5A300.16

- 5A300.20

- 5A300.25

- 5A300.32

- 5A300.50

- 5A300.6

- 5A300.60

- 5A300.7

- 5A300.75

- 5A300.8

- 5A330.10

- 5A330.100

- 5A330.11

- 5A330.12

- 5A330.14

- 5A330.16

- 5A330.20

- 5A330.25

- 5A330.32

- 5A330.50

- 5A330.6

- 5A330.60

- 5A330.7

- 5A330.75

- 5A330.8

- 5A330.85

- 5A340.10

- 5A340.100

- 5A340.11

- 5A340.12

- 5A340.14

- 5A340.16

- 5A340.20

- 5A340.25

- 5A340.32

- 5A340.50

- 5A340.6

- 5A340.60

- 5A340.7

- 5A340.75

- 5A340.8

- 5A375.10

- 5A375.100

- 5A375.11

- 5A375.12

- 5A375.14

- 5A375.16

- 5A375.20

- 5A375.25

- 5A375.32

- 5A375.50

- 5A375.6

- 5A375.60

- 5A375.7

- 5A375.75

- 5A375.8

- 5A390.10

- 5A390.100

- 5A390.11

- 5A390.12

- 5A390.14

- 5A390.16

- 5A390.20

- 5A390.25

- 5A390.32

- 5A390.50

- 5A390.6

- 5A390.60

- 5A390.7

- 5A390.75

- 5A390.8

- 5A420.10

- 5A420.100

- 5A420.11

- 5A420.12

- 5A420.14

- 5A420.16

- 5A420.20

- 5A420.25

- 5A420.32

- 5A420.50

- 5A420.6

- 5A420.60

- 5A420.7

- 5A420.75

- 5A420.8

- 5A450.10

- 5A450.100

- 5A450.11

- 5A450.12

- 5A450.14

- 5A450.16

- 5A450.20

- 5A450.25

- 5A450.32

- 5A450.50

- 5A450.6

- 5A450.60

- 5A450.7

- 5A450.75

- 5A450.8

- 5A455.10

- 5A455.100

- 5A455.11

- 5A455.12

- 5A455.14

- 5A455.16

- 5A455.20

- 5A455.25

- 5A455.32

- 5A455.50

- 5A455.6

- 5A455.60

- 5A455.7

- 5A455.75

- 5A455.8

- 5A480.10

- 5A480.100

- 5A480.11

- 5A480.12

- 5A480.14

- 5A480.16

- 5A480.20

- 5A480.25

- 5A480.32

- 5A480.50

- 5A480.6

- 5A480.60

- 5A480.7

- 5A480.75

- 5A480.8

- 5A490.10

- 5A490.100

- 5A490.11

- 5A490.12

- 5A490.14

- 5A490.16

- 5A490.20

- 5A490.25

- 5A490.32

- 5A490.50

- 5A490.6

- 5A490.60

- 5A490.7

- 5A490.75

- 5A490.8

- 5A500.10

- 5A500.100

- 5A500.11

- 5A500.12

- 5A500.14

- 5A500.16

- 5A500.20

- 5A500.25

- 5A500.32

- 5A500.50

- 5A500.6

- 5A500.60

- 5A500.7

- 5A500.75

- 5A500.8

- 5A525.10

- 5A525.100

- 5A525.11

- 5A525.12

- 5A525.14

- 5A525.16

- 5A525.20

- 5A525.25

- 5A525.32

- 5A525.50

- 5A525.6

- 5A525.60

- 5A525.7

- 5A525.75

- 5A525.8

- 5A545.10

- 5A545.100

- 5A545.11

- 5A545.12

- 5A545.130

- 5A545.14

- 5A545.16

- 5A545.20

- 5A545.25

- 5A545.32

- 5A545.50

- 5A545.6

- 5A545.60

- 5A545.7

- 5A545.75

- 5A545.8

- 5A600.10

- 5A600.100

- 5A600.11

- 5A600.12

- 5A600.14

- 5A600.16

- 5A600.20

- 5A600.25

- 5A600.32

- 5A600.50

- 5A600.6

- 5A600.60

- 5A600.7

- 5A600.75

- 5A600.8

- 5A610.10

- 5A610.100

- 5A610.11

- 5A610.12

- 5A610.14

- 5A610.16

- 5A610.20

- 5A610.25

- 5A610.32

- 5A610.45

- 5A610.50

- 5A610.6

- 5A610.60

- 5A610.7

- 5A610.75

- 5A610.8

- 5A620.10

- 5A620.100

- 5A620.11

- 5A620.12

- 5A620.14

- 5A620.16

- 5A620.20

- 5A620.25

- 5A620.32

- 5A620.50

- 5A620.6

- 5A620.60

- 5A620.7

- 5A620.75

- 5A620.8

- 5A630.10

- 5A630.100

- 5A630.11

- 5A630.12

- 5A630.14

- 5A630.16

- 5A630.20

- 5A630.25

- 5A630.32

- 5A630.50

- 5A630.6

- 5A630.60

- 5A630.7

- 5A630.75

- 5A630.8

- 5A660.10

- 5A660.100

- 5A660.11

- 5A660.12

- 5A660.14

- 5A660.16

- 5A660.20

- 5A660.25

- 5A660.32

- 5A660.50

- 5A660.6

- 5A660.60

- 5A660.7

- 5A660.75

- 5A660.8

- 5A710.10

- 5A710.100

- 5A710.11

- 5A710.12

- 5A710.14

- 5A710.16

- 5A710.20

- 5A710.25

- 5A710.32

- 5A710.50

- 5A710.6

- 5A710.60

- 5A710.7

- 5A710.75

- 5A710.8

- 5A720.10

- 5A720.100

- 5A720.11

- 5A720.12

- 5A720.14

- 5A720.16

- 5A720.20

- 5A720.25

- 5A720.32

- 5A720.43

- 5A720.50

- 5A720.6

- 5A720.60

- 5A720.7

- 5A720.75

- 5A720.8

- 5A750.10

- 5A750.100

- 5A750.11

- 5A750.12

- 5A750.14

- 5A750.16

- 5A750.20

- 5A750.25

- 5A750.32

- 5A750.50

- 5A750.6

- 5A750.60

- 5A750.7

- 5A750.75

- 5A750.8

- 5A780.10

- 5A780.100

- 5A780.11

- 5A780.12

- 5A780.14

- 5A780.16

- 5A780.20

- 5A780.25

- 5A780.30

- 5A780.32

- 5A780.50

- 5A780.6

- 5A780.60

- 5A780.7

- 5A780.75

- 5A780.8

- 5A825.10

- 5A825.100

- 5A825.11

- 5A825.12

- 5A825.14

- 5A825.16

- 5A825.20

- 5A825.25

- 5A825.32

- 5A825.50

- 5A825.6

- 5A825.60

- 5A825.7

- 5A825.75

- 5A825.8

- 5A860.10

- 5A860.100

- 5A860.11

- 5A860.12

- 5A860.14

- 5A860.16

- 5A860.20

- 5A860.25

- 5A860.32

- 5A860.50

- 5A860.6

- 5A860.60

- 5A860.7

- 5A860.75

- 5A860.8

- 5A975.10

- 5A975.100

- 5A975.11

- 5A975.12

- 5A975.14

- 5A975.16

- 5A975.20

- 5A975.25

- 5A975.32

- 5A975.50

- 5A975.6

- 5A975.60

- 5A975.7

- 5A975.75

- 5A975.8

- 10A1000.10

- 10A1000.100

- 10A1000.11

- 10A1000.12

- 10A1000.14

- 10A1000.16

- 10A1000.20

- 10A1000.25

- 10A1000.30

- 10A1000.32

- 10A1000.50

- 10A1000.6

- 10A1000.60

- 10A1000.7

- 10A1000.75

- 10A1000.8

- 10A1010.10

- 10A1010.100

- 10A1010.11

- 10A1010.12

- 10A1010.14

- 10A1010.16

- 10A1010.20

- 10A1010.25

- 10A1010.32

- 10A1010.50

- 10A1010.6

- 10A1010.60

- 10A1010.7

- 10A1010.75

- 10A1010.8

- 10A1050.10

- 10A1050.100

- 10A1050.11

- 10A1050.12

- 10A1050.14

- 10A1050.16

- 10A1050.20

- 10A1050.25

- 10A1050.32

- 10A1050.50

- 10A1050.6

- 10A1050.60

- 10A1050.7

- 10A1050.75

- 10A1050.8

- 10A1080.10

- 10A1080.100

- 10A1080.11

- 10A1080.12

- 10A1080.14

- 10A1080.16

- 10A1080.20

- 10A1080.25

- 10A1080.30

- 10A1080.32

- 10A1080.50

- 10A1080.6

- 10A1080.60

- 10A1080.7

- 10A1080.75

- 10A1080.8

- 10A1100.10

- 10A1100.100

- 10A1100.11

- 10A1100.12

- 10A1100.14

- 10A1100.16

- 10A1100.20

- 10A1100.25

- 10A1100.32

- 10A1100.50

- 10A1100.6

- 10A1100.60

- 10A1100.7

- 10A1100.75

- 10A1100.8

- 10A1150.10

- 10A1150.100

- 10A1150.11

- 10A1150.12

- 10A1150.14

- 10A1150.16

- 10A1150.20

- 10A1150.25

- 10A1150.32

- 10A1150.40

- 10A1150.50

- 10A1150.6

- 10A1150.60

- 10A1150.7

- 10A1150.75

- 10A1150.8

- 10A1200.10

- 10A1200.100

- 10A1200.11

- 10A1200.12

- 10A1200.120

- 10A1200.14

- 10A1200.16

- 10A1200.20

- 10A1200.25

- 10A1200.30

- 10A1200.32

- 10A1200.40

- 10A1200.50

- 10A1200.6

- 10A1200.60

- 10A1200.7

- 10A1200.75

- 10A1200.8

- 10A1210.10

- 10A1210.100

- 10A1210.11

- 10A1210.12

- 10A1210.14

- 10A1210.16

- 10A1210.20

- 10A1210.25

- 10A1210.32

- 10A1210.50

- 10A1210.6

- 10A1210.60

- 10A1210.7

- 10A1210.75

- 10A1210.8

- 10A1250.10

- 10A1250.100

- 10A1250.11

- 10A1250.12

- 10A1250.14

- 10A1250.16

- 10A1250.20

- 10A1250.25

- 10A1250.32

- 10A1250.50

- 10A1250.6

- 10A1250.60

- 10A1250.7

- 10A1250.75

- 10A1250.8

- 10A1280.10

- 10A1280.100

- 10A1280.11

- 10A1280.12

- 10A1280.120

- 10A1280.14

- 10A1280.16

- 10A1280.20

- 10A1280.25

- 10A1280.32

- 10A1280.50

- 10A1280.6

- 10A1280.60

- 10A1280.7

- 10A1280.75

- 10A1280.8

- 10A1300.10

- 10A1300.100

- 10A1300.11

- 10A1300.12

- 10A1300.14

- 10A1300.16

- 10A1300.20

- 10A1300.25

- 10A1300.32

- 10A1300.50

- 10A1300.6

- 10A1300.60

- 10A1300.7

- 10A1300.75

- 10A1300.8

- 10A1320.10

- 10A1320.100

- 10A1320.11

- 10A1320.12

- 10A1320.120

- 10A1320.14

- 10A1320.16

- 10A1320.20

- 10A1320.25

- 10A1320.32

- 10A1320.50

- 10A1320.6

- 10A1320.60

- 10A1320.7

- 10A1320.75

- 10A1320.8

- 10A1350.10

- 10A1350.100

- 10A1350.11

- 10A1350.12

- 10A1350.14

- 10A1350.16

- 10A1350.20

- 10A1350.25

- 10A1350.32

- 10A1350.50

- 10A1350.6

- 10A1350.60

- 10A1350.7

- 10A1350.75

- 10A1350.8

- 10A1360.10

- 10A1360.100

- 10A1360.11

- 10A1360.12

- 10A1360.14

- 10A1360.16

- 10A1360.20

- 10A1360.25

- 10A1360.32

- 10A1360.50

- 10A1360.6

- 10A1360.60

- 10A1360.7

- 10A1360.75

- 10A1360.8

- 10A1360.85

- 10A1400.10

- 10A1400.100

- 10A1400.11

- 10A1400.12

- 10A1400.14

- 10A1400.16

- 10A1400.20

- 10A1400.25

- 10A1400.32

- 10A1400.50

- 10A1400.6

- 10A1400.60

- 10A1400.7

- 10A1400.75

- 10A1400.8

- 10A1420.10

- 10A1420.100

- 10A1420.11

- 10A1420.12

- 10A1420.14

- 10A1420.16

- 10A1420.20

- 10A1420.25

- 10A1420.32

- 10A1420.50

- 10A1420.6

- 10A1420.60

- 10A1420.7

- 10A1420.75

- 10A1420.8

- 10A1480.10

- 10A1480.100

- 10A1480.11

- 10A1480.12

- 10A1480.14

- 10A1480.16

- 10A1480.20

- 10A1480.25

- 10A1480.32

- 10A1480.50

- 10A1480.6

- 10A1480.60

- 10A1480.7

- 10A1480.75

- 10A1480.8

- 10A1500.10

- 10A1500.100

- 10A1500.11

- 10A1500.12

- 10A1500.14

- 10A1500.150

- 10A1500.16

- 10A1500.20

- 10A1500.25

- 10A1500.32

- 10A1500.50

- 10A1500.6

- 10A1500.60

- 10A1500.7

- 10A1500.75

- 10A1500.8

- 10A1600.10

- 10A1600.100

- 10A1600.11

- 10A1600.12

- 10A1600.120

- 10A1600.14

- 10A1600.16

- 10A1600.20

- 10A1600.25

- 10A1600.32

- 10A1600.50

- 10A1600.6

- 10A1600.60

- 10A1600.7

- 10A1600.75

- 10A1600.8

- 10A1700.10

- 10A1700.100

- 10A1700.11

- 10A1700.12

- 10A1700.14

- 10A1700.16

- 10A1700.20

- 10A1700.25

- 10A1700.32

- 10A1700.50

- 10A1700.6

- 10A1700.60

- 10A1700.7

- 10A1700.75

- 10A1700.8

- 10A1720.10

- 10A1720.100

- 10A1720.11

- 10A1720.12

- 10A1720.14

- 10A1720.16

- 10A1720.20

- 10A1720.25

- 10A1720.32

- 10A1720.50

- 10A1720.6

- 10A1720.60

- 10A1720.7

- 10A1720.75

- 10A1720.8

- 10A1800.10

- 10A1800.100

- 10A1800.11

- 10A1800.12

- 10A1800.14

- 10A1800.16

- 10A1800.20

- 10A1800.25

- 10A1800.32

- 10A1800.50

- 10A1800.6

- 10A1800.60

- 10A1800.7

- 10A1800.75

- 10A1800.8

- 10A1860.10

- 10A1860.100

- 10A1860.11

- 10A1860.12

- 10A1860.14

- 10A1860.16

- 10A1860.20

- 10A1860.25

- 10A1860.32

- 10A1860.50

- 10A1860.6

- 10A1860.60

- 10A1860.7

- 10A1860.75

- 10A1860.8

- 10A1940.10

- 10A1940.100

- 10A1940.101

- 10A1940.11

- 10A1940.12

- 10A1940.14

- 10A1940.16

- 10A1940.20

- 10A1940.25

- 10A1940.32

- 10A1940.50

- 10A1940.6

- 10A1940.60

- 10A1940.7

- 10A1940.75

- 10A1940.8

- 10A1940.80

- 10A500.10

- 10A500.100

- 10A500.11

- 10A500.12

- 10A500.14

- 10A500.150 BVL

- 10A500.16

- 10A500.20

- 10A500.25

- 10A500.32

- 10A500.50

- 10A500.6

- 10A500.60

- 10A500.7

- 10A500.75

- 10A500.8

- 10A5340.25

- 10A560.10

- 10A560.100

- 10A560.11

- 10A560.12

- 10A560.14

- 10A560.150 BVL

- 10A560.16

- 10A560.20

- 10A560.25

- 10A560.32

- 10A560.50

- 10A560.6

- 10A560.60

- 10A560.7

- 10A560.75

- 10A560.8

- 10A580.10

- 10A580.16

- 10A580.32

- 10A580.50

- 10A600.10

- 10A600.100

- 10A600.11

- 10A600.12

- 10A600.14

- 10A600.16

- 10A600.20

- 10A600.25

- 10A600.32

- 10A600.50

- 10A600.6

- 10A600.60

- 10A600.7

- 10A600.75

- 10A600.8

- 10A610.10

- 10A610.100

- 10A610.11

- 10A610.12

- 10A610.14

- 10A610.16

- 10A610.20

- 10A610.25

- 10A610.32

- 10A610.50

- 10A610.6

- 10A610.60

- 10A610.7

- 10A610.75

- 10A610.8

- 10A660.10

- 10A660.100

- 10A660.11

- 10A660.12

- 10A660.14

- 10A660.16

- 10A660.20

- 10A660.25

- 10A660.32

- 10A660.35

- 10A660.50

- 10A660.6

- 10A660.60

- 10A660.7

- 10A660.75

- 10A660.8

- 10A700.10

- 10A700.100

- 10A700.11

- 10A700.12

- 10A700.14

- 10A700.16

- 10A700.20

- 10A700.200

- 10A700.25

- 10A700.30

- 10A700.32

- 10A700.50

- 10A700.6

- 10A700.60

- 10A700.7

- 10A700.75

- 10A700.8

- 10A730.10

- 10A730.100

- 10A730.11

- 10A730.12

- 10A730.14

- 10A730.16

- 10A730.20

- 10A730.25

- 10A730.32

- 10A730.50

- 10A730.6

- 10A730.60

- 10A730.7

- 10A730.75

- 10A730.8

- 10A780.10

- 10A780.100

- 10A780.11

- 10A780.12

- 10A780.14

- 10A780.16

- 10A780.20

- 10A780.25

- 10A780.32

- 10A780.40

- 10A780.50

- 10A780.6

- 10A780.60

- 10A780.7

- 10A780.75

- 10A780.8

- 10A800.10

- 10A800.100

- 10A800.11

- 10A800.12

- 10A800.14

- 10A800.150 BVL

- 10A800.16

- 10A800.20

- 10A800.25

- 10A800.30

- 10A800.32

- 10A800.50

- 10A800.6

- 10A800.60

- 10A800.7

- 10A800.75

- 10A800.8

- 10A840.10

- 10A840.100

- 10A840.11

- 10A840.12

- 10A840.14

- 10A840.16

- 10A840.20

- 10A840.25

- 10A840.32

- 10A840.50

- 10A840.6

- 10A840.60

- 10A840.7

- 10A840.75

- 10A840.8

- 10A880.10

- 10A880.100

- 10A880.11

- 10A880.12

- 10A880.14

- 10A880.16

- 10A880.20

- 10A880.25

- 10A880.32

- 10A880.50

- 10A880.6

- 10A880.60

- 10A880.7

- 10A880.75

- 10A880.8

- 10A890.10

- 10A890.100

- 10A890.11

- 10A890.12

- 10A890.14

- 10A890.16

- 10A890.20

- 10A890.25

- 10A890.32

- 10A890.50

- 10A890.6

- 10A890.60

- 10A890.7

- 10A890.75

- 10A890.8

- 10A920.10

- 10A920.100

- 10A920.11

- 10A920.12

- 10A920.14

- 10A920.16

- 10A920.20

- 10A920.25

- 10A920.32

- 10A920.40

- 10A920.50

- 10A920.6

- 10A920.60

- 10A920.7

- 10A920.75

- 10A920.8

- 10A960.10

- 10A960.100

- 10A960.11

- 10A960.12

- 10A960.14

- 10A960.16

- 10A960.20

- 10A960.25

- 10A960.32

- 10A960.50

- 10A960.6

- 10A960.60

- 10A960.7

- 10A960.75

- 10A960.8

- 10A980.10

- 10A980.100

- 10A980.11

- 10A980.12

- 10A980.14

- 10A980.16

- 10A980.20

- 10A980.25

- 10A980.32

- 10A980.50

- 10A980.6

- 10A980.60

- 10A980.7

- 10A980.75

- 10A980.8

- 20A1000.10

- 20A1000.100

- 20A1000.11

- 20A1000.12

- 20A1000.14

- 20A1000.16

- 20A1000.20

- 20A1000.25

- 20A1000.32

- 20A1000.50

- 20A1000.6

- 20A1000.60

- 20A1000.7

- 20A1000.75

- 20A1000.8

- 20A1100.10

- 20A1100.100

- 20A1100.11

- 20A1100.12

- 20A1100.14

- 20A1100.16

- 20A1100.20

- 20A1100.25

- 20A1100.32

- 20A1100.50

- 20A1100.6

- 20A1100.60

- 20A1100.7

- 20A1100.75

- 20A1100.8

- 20A1200.10

- 20A1200.100

- 20A1200.11

- 20A1200.12

- 20A1200.14

- 20A1200.16

- 20A1200.20

- 20A1200.25

- 20A1200.32

- 20A1200.50

- 20A1200.6

- 20A1200.60

- 20A1200.7

- 20A1200.75

- 20A1200.8

- 20A1260.10

- 20A1260.100

- 20A1260.11

- 20A1260.12

- 20A1260.14

- 20A1260.16

- 20A1260.20

- 20A1260.25

- 20A1260.32

- 20A1260.50

- 20A1260.6

- 20A1260.60

- 20A1260.7

- 20A1260.70

- 20A1260.75

- 20A1260.8

- 20A1500.10

- 20A1500.100

- 20A1500.11

- 20A1500.12

- 20A1500.14

- 20A1500.16

- 20A1500.20

- 20A1500.25

- 20A1500.32

- 20A1500.50

- 20A1500.6

- 20A1500.60

- 20A1500.7

- 20A1500.75

- 20A1500.8

- 20A1600.10

- 20A1600.100

- 20A1600.11

- 20A1600.12

- 20A1600.14

- 20A1600.150

- 20A1600.16

- 20A1600.20

- 20A1600.25

- 20A1600.32

- 20A1600.50

- 20A1600.6

- 20A1600.60

- 20A1600.7

- 20A1600.75

- 20A1600.8

- 20A1700.10

- 20A1700.100

- 20A1700.11

- 20A1700.12

- 20A1700.14

- 20A1700.16

- 20A1700.20

- 20A1700.25

- 20A1700.32

- 20A1700.50

- 20A1700.6

- 20A1700.60

- 20A1700.7

- 20A1700.75

- 20A1700.8

- 20A1760.10

- 20A1760.100

- 20A1760.11

- 20A1760.12

- 20A1760.14

- 20A1760.16

- 20A1760.20

- 20A1760.25

- 20A1760.32

- 20A1760.50

- 20A1760.6

- 20A1760.60

- 20A1760.7

- 20A1760.75

- 20A1760.8

- 20A1800.10

- 20A1800.100

- 20A1800.11

- 20A1800.12

- 20A1800.14

- 20A1800.150

- 20A1800.16

- 20A1800.20

- 20A1800.25

- 20A1800.32

- 20A1800.50

- 20A1800.6

- 20A1800.60

- 20A1800.7

- 20A1800.75

- 20A1800.8

- 20A1900.10

- 20A1900.100

- 20A1900.11

- 20A1900.12

- 20A1900.14

- 20A1900.16

- 20A1900.20

- 20A1900.25

- 20A1900.32

- 20A1900.50

- 20A1900.6

- 20A1900.60

- 20A1900.7

- 20A1900.75

- 20A1900.8

- 20A1960.10

- 20A1960.100

- 20A1960.11

- 20A1960.12

- 20A1960.14

- 20A1960.16

- 20A1960.20

- 20A1960.25

- 20A1960.32

- 20A1960.50

- 20A1960.6

- 20A1960.60

- 20A1960.7

- 20A1960.75

- 20A1960.8

- 2.5/120.10

- 2.5/120.11

- 2.5/120.12

- 2.5/120.14

- 2.5/120.16

- 2.5/120.20

- 2.5/120.25

- 2.5/120.32

- 2.5/120.4

- 2.5/120.50

- 2.5/120.6

- 2.5/120.7

- 2.5/120.8

- 2.5/1300.16

- 2.5/145.10

- 2.5/145.11

- 2.5/145.12

- 2.5/145.14

- 2.5/145.16

- 2.5/145.20

- 2.5/145.25

- 2.5/145.32

- 2.5/145.4

- 2.5/145.50

- 2.5/145.6

- 2.5/145.7

- 2.5/145.8

- 2.5/160.10

- 2.5/160.11

- 2.5/160.12

- 2.5/160.14

- 2.5/160.16

- 2.5/160.20

- 2.5/160.25

- 2.5/160.32

- 2.5/160.4

- 2.5/160.50

- 2.5/160.6

- 2.5/160.7

- 2.5/160.8

- 2.5/177.10

- 2.5/177.11

- 2.5/177.12

- 2.5/177.14

- 2.5/177.16

- 2.5/177.20

- 2.5/177.25

- 2.5/177.32

- 2.5/177.4

- 2.5/177.50

- 2.5/177.6

- 2.5/177.7

- 2.5/177.8

- 2.5/180.10

- 2.5/180.11

- 2.5/180.12

- 2.5/180.14

- 2.5/180.16

- 2.5/180.20

- 2.5/180.25

- 2.5/180.32

- 2.5/180.4

- 2.5/180.50

- 2.5/180.6

- 2.5/180.7

- 2.5/180.8

- 2.5/182.10

- 2.5/182.11

- 2.5/182.12

- 2.5/182.14

- 2.5/182.16

- 2.5/182.20

- 2.5/182.25

- 2.5/182.32

- 2.5/182.4

- 2.5/182.50

- 2.5/182.6

- 2.5/182.7

- 2.5/182.8

- 2.5/200.10

- 2.5/200.11

- 2.5/200.12

- 2.5/200.14

- 2.5/200.16

- 2.5/200.20

- 2.5/200.25

- 2.5/200.32

- 2.5/200.4

- 2.5/200.50

- 2.5/200.6

- 2.5/200.7

- 2.5/200.8

- 2.5/210.10

- 2.5/210.11

- 2.5/210.12

- 2.5/210.14

- 2.5/210.16

- 2.5/210.20

- 2.5/210.25

- 2.5/210.32

- 2.5/210.4

- 2.5/210.50

- 2.5/210.6

- 2.5/210.7

- 2.5/210.8

- 2.5/225.10

- 2.5/225.11

- 2.5/225.12

- 2.5/225.14

- 2.5/225.16

- 2.5/225.20

- 2.5/225.25

- 2.5/225.32

- 2.5/225.4

- 2.5/225.50

- 2.5/225.6

- 2.5/225.7

- 2.5/225.8

- 2.5/230.10

- 2.5/230.11

- 2.5/230.12

- 2.5/230.14

- 2.5/230.16

- 2.5/230.20

- 2.5/230.25

- 2.5/230.32

- 2.5/230.4

- 2.5/230.50

- 2.5/230.6

- 2.5/230.7

- 2.5/230.8

- 2.5/245.10

- 2.5/245.11

- 2.5/245.12

- 2.5/245.14

- 2.5/245.16

- 2.5/245.20

- 2.5/245.25

- 2.5/245.30

- 2.5/245.32

- 2.5/245.4

- 2.5/245.50

- 2.5/245.6

- 2.5/245.7

- 2.5/245.8

- 2.5/265.10

- 2.5/265.11

- 2.5/265.12

- 2.5/265.14

- 2.5/265.15

- 2.5/265.16

- 2.5/265.20

- 2.5/265.25

- 2.5/265.32

- 2.5/265.4

- 2.5/265.50

- 2.5/265.6

- 2.5/265.7

- 2.5/265.8

- 2.5/277.10

- 2.5/277.11

- 2.5/277.12

- 2.5/277.14

- 2.5/277.16

- 2.5/277.20

- 2.5/277.25

- 2.5/277.32

- 2.5/277.4

- 2.5/277.50

- 2.5/277.6

- 2.5/277.7

- 2.5/277.8

- 2.5/285.10

- 2.5/285.11

- 2.5/285.12

- 2.5/285.14

- 2.5/285.16

- 2.5/285.20

- 2.5/285.25

- 2.5/285.32

- 2.5/285.4

- 2.5/285.50

- 2.5/285.6

- 2.5/285.7

- 2.5/285.8

- 2.5/290.10

- 2.5/290.11

- 2.5/290.12

- 2.5/290.14

- 2.5/290.16

- 2.5/290.20

- 2.5/290.25

- 2.5/290.32

- 2.5/290.4

- 2.5/290.50

- 2.5/290.6

- 2.5/290.7

- 2.5/290.8

- 2.5/305.10

- 2.5/305.11

- 2.5/305.12

- 2.5/305.14

- 2.5/305.16

- 2.5/305.20

- 2.5/305.25

- 2.5/305.32

- 2.5/305.4

- 2.5/305.50

- 2.5/305.6

- 2.5/305.7

- 2.5/305.8

- 2.5/317.10

- 2.5/317.11

- 2.5/317.12

- 2.5/317.14

- 2.5/317.16

- 2.5/317.20

- 2.5/317.200

- 2.5/317.25

- 2.5/317.32

- 2.5/317.4

- 2.5/317.50

- 2.5/317.6

- 2.5/317.7

- 2.5/317.8

- 2.5/330.10

- 2.5/330.11

- 2.5/330.12

- 2.5/330.14

- 2.5/330.16

- 2.5/330.20

- 2.5/330.25

- 2.5/330.30

- 2.5/330.32

- 2.5/330.4

- 2.5/330.50

- 2.5/330.6

- 2.5/330.7

- 2.5/330.8

- 2.5/380.10

- 2.5/380.11

- 2.5/380.12

- 2.5/380.14

- 2.5/380.16

- 2.5/380.20

- 2.5/380.25

- 2.5/380.32

- 2.5/380.4

- 2.5/380.50

- 2.5/380.6

- 2.5/380.7

- 2.5/380.8

- 2.5/420.10

- 2.5/420.11

- 2.5/420.12

- 2.5/420.14

- 2.5/420.16

- 2.5/420.20

- 2.5/420.200

- 2.5/420.25

- 2.5/420.32

- 2.5/420.4

- 2.5/420.4 1/3

- 2.5/420.50

- 2.5/420.6

- 2.5/420.6 1/3

- 2.5/420.7

- 2.5/420.8

- 2.5/480.10

- 2.5/480.11

- 2.5/480.12

- 2.5/480.14

- 2.5/480.16

- 2.5/480.20

- 2.5/480.25

- 2.5/480.32

- 2.5/480.4

- 2.5/480.4 1/3

- 2.5/480.50

- 2.5/480.6

- 2.5/480.7

- 2.5/480.8

- 2.5/500.10

- 2.5/500.11

- 2.5/500.12

- 2.5/500.14

- 2.5/500.16

- 2.5/500.20

- 2.5/500.200

- 2.5/500.25

- 2.5/500.32

- 2.5/500.4

- 2.5/500.50

- 2.5/500.6

- 2.5/500.7

- 2.5/500.8

- 2.5/500.8 1/3*

- 2.5/600.10

- 2.5/600.11

- 2.5/600.12

- 2.5/600.14

- 2.5/600.16

- 2.5/600.20

- 2.5/600.25

- 2.5/600.32

- 2.5/600.37

- 2.5/600.4

- 2.5/600.50

- 2.5/600.6

- 2.5/600.60

- 2.5/600.7

- 2.5/600.8

- 2.5/620.10

- 2.5/620.11

- 2.5/620.12

- 2.5/620.14

- 2.5/620.16

- 2.5/620.20

- 2.5/620.25

- 2.5/620.32

- 2.5/620.4

- 2.5/620.50

- 2.5/620.6

- 2.5/620.7

- 2.5/620.8

- 2.5/620.8 1/3

- 2.5/650.10

- 2.5/650.11

- 2.5/650.12

- 2.5/650.14

- 2.5/650.16

- 2.5/650.20

- 2.5/650.25

- 2.5/650.32

- 2.5/650.4

- 2.5/650.50

- 2.5/650.6

- 2.5/650.7

- 2.5/650.8

- 2.5/780.10

- 2.5/780.11

- 2.5/780.12

- 2.5/780.14

- 2.5/780.16

- 2.5/780.20

- 2.5/780.25

- 2.5/780.32

- 2.5/780.4

- 2.5/780.50

- 2.5/780.6

- 2.5/780.7

- 2.5/780.8

- 2.5/880.10

- 2.5/880.11

- 2.5/880.12

- 2.5/880.14

- 2.5/880.16

- 2.5/880.20

- 2.5/880.25

- 2.5/880.32

- 2.5/880.4

- 2.5/880.50

- 2.5/880.6

- 2.5/880.7

- 2.5/880.8

- 2.5/915.10

- 2.5/915.11

- 2.5/915.12

- 2.5/915.14

- 2.5/915.16

- 2.5/915.20

- 2.5/915.25

- 2.5/915.32

- 2.5/915.4

- 2.5/915.50

- 2.5/915.6

- 2.5/915.7

- 2.5/915.8

- 2.5/950.10

- 2.5/950.11

- 2.5/950.12

- 2.5/950.14

- 2.5/950.16

- 2.5/950.20

- 2.5/950.225

- 2.5/950.25

- 2.5/950.32

- 2.5/950.4

- 2.5/950.50

- 2.5/950.6

- 2.5/950.7

- 2.5/950.8

- 5.100.12

- 5.100.25

- 5.1000.10

- 5.1000.100

- 5.1000.11

- 5.1000.12

- 5.1000.14

- 5.1000.16

- 5.1000.20

- 5.1000.25

- 5.1000.32

- 5.1000.4

- 5.1000.50

- 5.1000.6

- 5.1000.60

- 5.1000.7

- 5.1000.75

- 5.1000.8

- 5.1000.9

- 5.1075.10

- 5.1075.100

- 5.1075.11

- 5.1075.12

- 5.1075.125

- 5.1075.130

- 5.1075.14

- 5.1075.16

- 5.1075.20

- 5.1075.25

- 5.1075.32

- 5.1075.4

- 5.1075.50

- 5.1075.6

- 5.1075.60

- 5.1075.7

- 5.1075.75

- 5.1075.8

- 5.1075.9

- 5.1100.10

- 5.1100.100

- 5.1100.11

- 5.1100.12

- 5.1100.14

- 5.1100.16

- 5.1100.20

- 5.1100.25

- 5.1100.32

- 5.1100.4

- 5.1100.50

- 5.1100.6

- 5.1100.60

- 5.1100.7

- 5.1100.75

- 5.1100.8

- 5.1100.9

- 5.1140.10

- 5.1140.100

- 5.1140.11

- 5.1140.12

- 5.1140.14

- 5.1140.16

- 5.1140.20

- 5.1140.25

- 5.1140.32

- 5.1140.4

- 5.1140.50

- 5.1140.6

- 5.1140.60

- 5.1140.7

- 5.1140.75

- 5.1140.8

- 5.1140.9

- 5.1160.10

- 5.1160.100

- 5.1160.11

- 5.1160.12

- 5.1160.125

- 5.1160.130

- 5.1160.14

- 5.1160.16

- 5.1160.20

- 5.1160.25

- 5.1160.32

- 5.1160.4

- 5.1160.50

- 5.1160.6

- 5.1160.60

- 5.1160.7

- 5.1160.75

- 5.1160.8

- 5.1160.9

- 5.1215.10

- 5.1215.100

- 5.1215.11

- 5.1215.12

- 5.1215.14

- 5.1215.16

- 5.1215.20

- 5.1215.25

- 5.1215.30

- 5.1215.32

- 5.1215.4

- 5.1215.50

- 5.1215.6

- 5.1215.60

- 5.1215.7

- 5.1215.70

- 5.1215.75

- 5.1215.8

- 5.1215.9

- 5.1275.10

- 5.1275.100

- 5.1275.11

- 5.1275.12

- 5.1275.14

- 5.1275.16

- 5.1275.20

- 5.1275.25

- 5.1275.32

- 5.1275.4

- 5.1275.50

- 5.1275.6

- 5.1275.60

- 5.1275.7

- 5.1275.75

- 5.1275.8

- 5.1275.9

- 5.1315.10

- 5.1315.100

- 5.1315.11

- 5.1315.12

- 5.1315.14

- 5.1315.16

- 5.1315.20

- 5.1315.25

- 5.1315.32

- 5.1315.35

- 5.1315.4

- 5.1315.50

- 5.1315.6

- 5.1315.60

- 5.1315.7

- 5.1315.75

- 5.1315.8

- 5.1315.9

- 5.1350.10

- 5.1350.100

- 5.1350.11

- 5.1350.12

- 5.1350.14

- 5.1350.16

- 5.1350.20

- 5.1350.25

- 5.1350.32

- 5.1350.4

- 5.1350.50

- 5.1350.6

- 5.1350.60

- 5.1350.7

- 5.1350.75

- 5.1350.8

- 5.1350.9

- 5.1355.10

- 5.1355.100

- 5.1355.11

- 5.1355.12

- 5.1355.14

- 5.1355.16

- 5.1355.20

- 5.1355.25

- 5.1355.32

- 5.1355.4

- 5.1355.50

- 5.1355.6

- 5.1355.60

- 5.1355.7

- 5.1355.75

- 5.1355.8

- 5.1355.9

- 5.1380.10

- 5.1380.100

- 5.1380.11

- 5.1380.12

- 5.1380.135

- 5.1380.14

- 5.1380.16

- 5.1380.170

- 5.1380.175

- 5.1380.20

- 5.1380.25

- 5.1380.270

- 5.1380.30

- 5.1380.32

- 5.1380.340

- 5.1380.4

- 5.1380.50

- 5.1380.6

- 5.1380.60

- 5.1380.7

- 5.1380.75

- 5.1380.8

- 5.1380.9

- 5.1380.90

- 5.1440.10

- 5.1440.100

- 5.1440.11

- 5.1440.12

- 5.1440.14

- 5.1440.16

- 5.1440.20

- 5.1440.25

- 5.1440.32

- 5.1440.4

- 5.1440.50

- 5.1440.6

- 5.1440.60

- 5.1440.7

- 5.1440.75

- 5.1440.8

- 5.1440.9

- 5.150.10

- 5.150.100

- 5.150.11

- 5.150.12

- 5.150.14

- 5.150.16

- 5.150.160

- 5.150.20

- 5.150.25

- 5.150.32

- 5.150.4

- 5.150.50

- 5.150.6

- 5.150.60

- 5.150.7

- 5.150.75

- 5.150.8

- 5.150.9

- 5.1500.10

- 5.1500.100

- 5.1500.11

- 5.1500.12

- 5.1500.14

- 5.1500.16

- 5.1500.20

- 5.1500.25

- 5.1500.32

- 5.1500.4

- 5.1500.50

- 5.1500.6

- 5.1500.60

- 5.1500.7

- 5.1500.75

- 5.1500.8

- 5.1500.9

- 5.165.10

- 5.165.100

- 5.165.11

- 5.165.12

- 5.165.14

- 5.165.16

- 5.165.20

- 5.165.25

- 5.165.32

- 5.165.4

- 5.165.50

- 5.165.6

- 5.165.60

- 5.165.7

- 5.165.75

- 5.165.8

- 5.165.9

- 5.1715.16

- 5.180.10

- 5.180.100

- 5.180.11

- 5.180.12

- 5.180.14

- 5.180.16

- 5.180.20

- 5.180.25

- 5.180.32

- 5.180.4

- 5.180.50

- 5.180.6

- 5.180.60

- 5.180.7

- 5.180.75

- 5.180.8

- 5.180.9

- 5.185.10

- 5.185.100

- 5.185.11

- 5.185.12

- 5.185.14

- 5.185.16

- 5.185.20

- 5.185.25

- 5.185.32

- 5.185.4

- 5.185.50

- 5.185.6

- 5.185.60

- 5.185.7

- 5.185.75

- 5.185.8

- 5.185.9

- 5.200.10

- 5.200.100

- 5.200.11

- 5.200.12

- 5.200.14

- 5.200.16

- 5.200.20

- 5.200.25

- 5.200.32

- 5.200.4

- 5.200.50

- 5.200.6

- 5.200.60

- 5.200.7

- 5.200.75

- 5.200.8

- 5.200.9

- 5.210.10

- 5.210.100

- 5.210.11

- 5.210.12

- 5.210.14

- 5.210.16

- 5.210.20

- 5.210.25

- 5.210.32

- 5.210.4

- 5.210.50

- 5.210.6

- 5.210.60

- 5.210.7

- 5.210.75

- 5.210.8

- 5.210.9

- 5.215.10

- 5.215.100

- 5.215.11

- 5.215.12

- 5.215.14

- 5.215.16

- 5.215.20

- 5.215.25

- 5.215.32

- 5.215.4

- 5.215.50

- 5.215.6

- 5.215.60

- 5.215.7

- 5.215.75

- 5.215.8

- 5.215.9

- 5.220.10

- 5.220.100

- 5.220.11

- 5.220.12

- 5.220.14

- 5.220.16

- 5.220.20

- 5.220.25

- 5.220.32

- 5.220.4

- 5.220.50

- 5.220.6

- 5.220.60

- 5.220.7

- 5.220.75

- 5.220.8

- 5.220.9

- 5.225.10

- 5.225.100

- 5.225.11

- 5.225.12

- 5.225.14

- 5.225.16

- 5.225.20

- 5.225.25

- 5.225.32

- 5.225.4

- 5.225.50

- 5.225.6

- 5.225.60

- 5.225.7

- 5.225.75

- 5.225.8

- 5.225.9

- 5.245.10

- 5.245.100

- 5.245.11

- 5.245.12

- 5.245.14

- 5.245.16

- 5.245.20

- 5.245.25

- 5.245.30

- 5.245.32

- 5.245.4

- 5.245.50

- 5.245.6

- 5.245.60

- 5.245.7

- 5.245.75

- 5.245.8

- 5.245.9

- 5.250.10

- 5.250.100

- 5.250.11

- 5.250.12

- 5.250.14

- 5.250.16

- 5.250.20

- 5.250.25

- 5.250.32

- 5.250.4

- 5.250.50

- 5.250.6

- 5.250.60

- 5.250.7

- 5.250.75

- 5.250.8

- 5.250.9

- 5.255.10

- 5.255.100

- 5.255.11

- 5.255.12

- 5.255.14

- 5.255.16

- 5.255.20

- 5.255.25

- 5.255.32

- 5.255.4

- 5.255.50

- 5.255.6

- 5.255.60

- 5.255.7

- 5.255.75

- 5.255.8

- 5.255.9

- 5.260.10

- 5.260.100

- 5.260.11

- 5.260.12

- 5.260.14

- 5.260.15

- 5.260.16

- 5.260.20

- 5.260.25

- 5.260.32

- 5.260.4

- 5.260.50

- 5.260.6

- 5.260.60

- 5.260.7

- 5.260.75

- 5.260.8

- 5.260.9

- 5.270.10

- 5.270.100

- 5.270.11

- 5.270.12

- 5.270.14

- 5.270.16

- 5.270.20

- 5.270.25

- 5.270.32

- 5.270.4

- 5.270.50

- 5.270.6

- 5.270.60

- 5.270.7

- 5.270.75

- 5.270.8

- 5.270.9

- 5.280.10

- 5.280.100

- 5.280.11

- 5.280.12

- 5.280.14

- 5.280.16

- 5.280.20

- 5.280.25

- 5.280.32

- 5.280.4

- 5.280.50

- 5.280.6

- 5.280.60

- 5.280.7

- 5.280.75

- 5.280.8

- 5.280.9

- 5.295.10

- 5.295.100

- 5.295.11

- 5.295.12

- 5.295.14

- 5.295.16

- 5.295.20

- 5.295.25

- 5.295.32

- 5.295.4

- 5.295.50

- 5.295.6

- 5.295.60

- 5.295.7

- 5.295.75

- 5.295.8

- 5.295.9

- 5.300.10

- 5.300.100

- 5.300.11

- 5.300.12

- 5.300.14

- 5.300.16

- 5.300.20

- 5.300.25

- 5.300.32

- 5.300.4

- 5.300.50

- 5.300.6

- 5.300.60

- 5.300.7

- 5.300.75

- 5.300.8

- 5.300.9

- 5.305.10

- 5.305.100

- 5.305.11

- 5.305.12

- 5.305.14

- 5.305.16

- 5.305.160

- 5.305.20

- 5.305.25

- 5.305.32

- 5.305.4

- 5.305.50

- 5.305.6

- 5.305.60

- 5.305.7

- 5.305.75

- 5.305.8

- 5.305.9

- 5.325.10

- 5.325.100

- 5.325.11

- 5.325.12

- 5.325.14

- 5.325.16

- 5.325.20

- 5.325.25

- 5.325.32

- 5.325.4

- 5.325.50

- 5.325.6

- 5.325.60

- 5.325.7

- 5.325.75

- 5.325.8

- 5.325.9

- 5.330.10

- 5.330.100

- 5.330.11

- 5.330.12

- 5.330.14

- 5.330.150

- 5.330.16

- 5.330.20

- 5.330.25

- 5.330.32

- 5.330.4

- 5.330.50

- 5.330.6

- 5.330.60

- 5.330.7

- 5.330.75

- 5.330.8

- 5.330.9

- 5.340.10

- 5.340.100

- 5.340.11

- 5.340.12

- 5.340.14

- 5.340.16

- 5.340.20

- 5.340.25

- 5.340.32

- 5.340.4

- 5.340.50

- 5.340.6

- 5.340.60

- 5.340.7

- 5.340.75

- 5.340.8

- 5.340.9

- 5.350.10

- 5.350.100

- 5.350.11

- 5.350.12

- 5.350.14

- 5.350.16

- 5.350.20

- 5.350.25

- 5.350.32

- 5.350.4

- 5.350.50

- 5.350.6

- 5.350.60

- 5.350.7

- 5.350.75

- 5.350.8

- 5.350.9

- 5.355.10

- 5.355.100

- 5.355.11

- 5.355.12

- 5.355.14

- 5.355.16

- 5.355.20

- 5.355.25

- 5.355.32

- 5.355.4

- 5.355.50

- 5.355.6

- 5.355.60

- 5.355.7

- 5.355.75

- 5.355.8

- 5.355.9

- 5.3550.20

- 5.360.10

- 5.360.100

- 5.360.11

- 5.360.12

- 5.360.14

- 5.360.16

- 5.360.20

- 5.360.25

- 5.360.32

- 5.360.4

- 5.360.50

- 5.360.6

- 5.360.60

- 5.360.7

- 5.360.75

- 5.360.8

- 5.360.9

- 5.365.10

- 5.365.100

- 5.365.11

- 5.365.12

- 5.365.14

- 5.365.16

- 5.365.20

- 5.365.25

- 5.365.32

- 5.365.4

- 5.365.40

- 5.365.50

- 5.365.6

- 5.365.60

- 5.365.7

- 5.365.75

- 5.365.8

- 5.365.9

- 5.375.10

- 5.375.11

- 5.375.12

- 5.375.14

- 5.375.16

- 5.375.20

- 5.375.25

- 5.375.32

- 5.375.4

- 5.375.50

- 5.375.6

- 5.375.60

- 5.375.7

- 5.375.75

- 5.375.8

- 5.390.10

- 5.390.100

- 5.390.11

- 5.390.12

- 5.390.14

- 5.390.150

- 5.390.16

- 5.390.20

- 5.390.25

- 5.390.30

- 5.390.32

- 5.390.4

- 5.390.50

- 5.390.6

- 5.390.60

- 5.390.7

- 5.390.75

- 5.390.8

- 5.390.9

- 5.400.10

- 5.400.100

- 5.400.11

- 5.400.12

- 5.400.14

- 5.400.16

- 5.400.20

- 5.400.25

- 5.400.32

- 5.400.4

- 5.400.50

- 5.400.6

- 5.400.60

- 5.400.7

- 5.400.75

- 5.400.8

- 5.400.9

- 5.410.10

- 5.410.100

- 5.410.11

- 5.410.12

- 5.410.132

- 5.410.14

- 5.410.16

- 5.410.20

- 5.410.25

- 5.410.30

- 5.410.32

- 5.410.4

- 5.410.50

- 5.410.6

- 5.410.60

- 5.410.7

- 5.410.75

- 5.410.8

- 5.410.82

- 5.410.9

- 5.420.10

- 5.420.100

- 5.420.105

- 5.420.11

- 5.420.12

- 5.420.130

- 5.420.14

- 5.420.150

- 5.420.16

- 5.420.180

- 5.420.20

- 5.420.25

- 5.420.32

- 5.420.4

- 5.420.50

- 5.420.6

- 5.420.60

- 5.420.7

- 5.420.75

- 5.420.8

- 5.420.9

- 5.425.10

- 5.425.100

- 5.425.11

- 5.425.12

- 5.425.14

- 5.425.16

- 5.425.20

- 5.425.25

- 5.425.32

- 5.425.4

- 5.425.50

- 5.425.6

- 5.425.60

- 5.425.7

- 5.425.75

- 5.425.8

- 5.425.9

- 5.430.10

- 5.430.100

- 5.430.11

- 5.430.12

- 5.430.14

- 5.430.16

- 5.430.20

- 5.430.25

- 5.430.32

- 5.430.4

- 5.430.50

- 5.430.6

- 5.430.60

- 5.430.7

- 5.430.75

- 5.430.8

- 5.430.9

- 5.440.10

- 5.440.100

- 5.440.11

- 5.440.12

- 5.440.14

- 5.440.16

- 5.440.20

- 5.440.25

- 5.440.32

- 5.440.4

- 5.440.50

- 5.440.6

- 5.440.60

- 5.440.7

- 5.440.8

- 5.440.9

- 5.445.10

- 5.445.100

- 5.445.11

- 5.445.12

- 5.445.14

- 5.445.16

- 5.445.20

- 5.445.25

- 5.445.32

- 5.445.4

- 5.445.50

- 5.445.6

- 5.445.60

- 5.445.7

- 5.445.75

- 5.445.8

- 5.445.9

- 5.450.10

- 5.450.100

- 5.450.11

- 5.450.12

- 5.450.14

- 5.450.16

- 5.450.20

- 5.450.25

- 5.450.32

- 5.450.4

- 5.450.50

- 5.450.6

- 5.450.60

- 5.450.7

- 5.450.75

- 5.450.8

- 5.450.9

- 5.455.10

- 5.455.100

- 5.455.11

- 5.455.12

- 5.455.14

- 5.455.16

- 5.455.17

- 5.455.20

- 5.455.25

- 5.455.30

- 5.455.32

- 5.455.4

- 5.455.50

- 5.455.6

- 5.455.60

- 5.455.7

- 5.455.75

- 5.455.8

- 5.455.9

- 5.460.10

- 5.460.100

- 5.460.11

- 5.460.12

- 5.460.14

- 5.460.16

- 5.460.20

- 5.460.25

- 5.460.32

- 5.460.4

- 5.460.50

- 5.460.6

- 5.460.60

- 5.460.7

- 5.460.75

- 5.460.8

- 5.460.9

- 5.475.10

- 5.475.100

- 5.475.11

- 5.475.12

- 5.475.14

- 5.475.16

- 5.475.18

- 5.475.20

- 5.475.25

- 5.475.32

- 5.475.4

- 5.475.50

- 5.475.6

- 5.475.60

- 5.475.7

- 5.475.75

- 5.475.8

- 5.475.9

- 5.480.10

- 5.480.100

- 5.480.11

- 5.480.12

- 5.480.14

- 5.480.16

- 5.480.18

- 5.480.20

- 5.480.25

- 5.480.30

- 5.480.32

- 5.480.4

- 5.480.40

- 5.480.50

- 5.480.6

- 5.480.60

- 5.480.7

- 5.480.75

- 5.480.8

- 5.480.9

- 5.500.10

- 5.500.100

- 5.500.11

- 5.500.12

- 5.500.14

- 5.500.16

- 5.500.20

- 5.500.225

- 5.500.25

- 5.500.30

- 5.500.32

- 5.500.4

- 5.500.50

- 5.500.6

- 5.500.60

- 5.500.7

- 5.500.75

- 5.500.8

- 5.500.9

- 5.510.10

- 5.510.100

- 5.510.11

- 5.510.12

- 5.510.120

- 5.510.14

- 5.510.16

- 5.510.20

- 5.510.25

- 5.510.32

- 5.510.4

- 5.510.50

- 5.510.6

- 5.510.60

- 5.510.7

- 5.510.75

- 5.510.8

- 5.510.9

- 5.525.10

- 5.525.100

- 5.525.11

- 5.525.12

- 5.525.14

- 5.525.16

- 5.525.20

- 5.525.25

- 5.525.32

- 5.525.4

- 5.525.50

- 5.525.6

- 5.525.60

- 5.525.7

- 5.525.75

- 5.525.8

- 5.525.9

- 5.530.10

- 5.530.100

- 5.530.11

- 5.530.12

- 5.530.14

- 5.530.16

- 5.530.20

- 5.530.25

- 5.530.32

- 5.530.4

- 5.530.50

- 5.530.6

- 5.530.60

- 5.530.7

- 5.530.75

- 5.530.8

- 5.530.9

- 5.545.10

- 5.545.100

- 5.545.11

- 5.545.12

- 5.545.14

- 5.545.16

- 5.545.20

- 5.545.25

- 5.545.32

- 5.545.4

- 5.545.50

- 5.545.6

- 5.545.60

- 5.545.7

- 5.545.75

- 5.545.8

- 5.545.9

- 5.550.10

- 5.550.100

- 5.550.11

- 5.550.12

- 5.550.14

- 5.550.16

- 5.550.20

- 5.550.25

- 5.550.32

- 5.550.4

- 5.550.50

- 5.550.6

- 5.550.60

- 5.550.7

- 5.550.75

- 5.550.8

- 5.550.9

- 5.560.10

- 5.560.100

- 5.560.105

- 5.560.11

- 5.560.12

- 5.560.14

- 5.560.16

- 5.560.160

- 5.560.20

- 5.560.25

- 5.560.30

- 5.560.32

- 5.560.4

- 5.560.50

- 5.560.6

- 5.560.60

- 5.560.7

- 5.560.75

- 5.560.8

- 5.560.9

- 5.575.10

- 5.575.100

- 5.575.11

- 5.575.12

- 5.575.14

- 5.575.16

- 5.575.20

- 5.575.225

- 5.575.25

- 5.575.30

- 5.575.32

- 5.575.4

- 5.575.50

- 5.575.6

- 5.575.60

- 5.575.7

- 5.575.75

- 5.575.8

- 5.575.9

- 5.590.10

- 5.590.100

- 5.590.11

- 5.590.12

- 5.590.14

- 5.590.16

- 5.590.20

- 5.590.25

- 5.590.32

- 5.590.4

- 5.590.50

- 5.590.6

- 5.590.60

- 5.590.7

- 5.590.75

- 5.590.8

- 5.590.9

- 5.600.10

- 5.600.100

- 5.600.11

- 5.600.12

- 5.600.14

- 5.600.16

- 5.600.20

- 5.600.25

- 5.600.32

- 5.600.4

- 5.600.50

- 5.600.6

- 5.600.60

- 5.600.7

- 5.600.75

- 5.600.8

- 5.600.9

- 5.605.10

- 5.605.100

- 5.605.11

- 5.605.12

- 5.605.14

- 5.605.16

- 5.605.20

- 5.605.25

- 5.605.32

- 5.605.4

- 5.605.50

- 5.605.6

- 5.605.60

- 5.605.7

- 5.605.75

- 5.605.8

- 5.605.9

- 5.610.10

- 5.610.100

- 5.610.11

- 5.610.12

- 5.610.14

- 5.610.16

- 5.610.17

- 5.610.20

- 5.610.25

- 5.610.32

- 5.610.4

- 5.610.50

- 5.610.6

- 5.610.60

- 5.610.7

- 5.610.75

- 5.610.8

- 5.610.9

- 5.620.10

- 5.620.100

- 5.620.11

- 5.620.12

- 5.620.14

- 5.620.16

- 5.620.20

- 5.620.25

- 5.620.30

- 5.620.32

- 5.620.4

- 5.620.50

- 5.620.6

- 5.620.60

- 5.620.7

- 5.620.75

- 5.620.8

- 5.620.9

- 5.625.10

- 5.625.100

- 5.625.11

- 5.625.12

- 5.625.14

- 5.625.16

- 5.625.20

- 5.625.25

- 5.625.32

- 5.625.4

- 5.625.50

- 5.625.6

- 5.625.60

- 5.625.7

- 5.625.75

- 5.625.8

- 5.625.9

- 5.630.10

- 5.630.100

- 5.630.11

- 5.630.12

- 5.630.14

- 5.630.15

- 5.630.16

- 5.630.20

- 5.630.25

- 5.630.30

- 5.630.32

- 5.630.4

- 5.630.50

- 5.630.6

- 5.630.60

- 5.630.7

- 5.630.75

- 5.630.8

- 5.640.10

- 5.640.100

- 5.640.11

- 5.640.12

- 5.640.14

- 5.640.16

- 5.640.20

- 5.640.25

- 5.640.32

- 5.640.4

- 5.640.50

- 5.640.6

- 5.640.60

- 5.640.7

- 5.640.75

- 5.640.8

- 5.640.9

- 5.650.10

- 5.650.100

- 5.650.11

- 5.650.12

- 5.650.14

- 5.650.16

- 5.650.20

- 5.650.25

- 5.650.32

- 5.650.4

- 5.650.50

- 5.650.6

- 5.650.60

- 5.650.7

- 5.650.75

- 5.650.8

- 5.650.9

- 5.660.10

- 5.660.100

- 5.660.11

- 5.660.12

- 5.660.14

- 5.660.16

- 5.660.20

- 5.660.200

- 5.660.25

- 5.660.32

- 5.660.4

- 5.660.50

- 5.660.6

- 5.660.60

- 5.660.7

- 5.660.75

- 5.660.8

- 5.660.9

- 5.670.10

- 5.670.100

- 5.670.11

- 5.670.12

- 5.670.14

- 5.670.16

- 5.670.20

- 5.670.25

- 5.670.32

- 5.670.4

- 5.670.50

- 5.670.6

- 5.670.60

- 5.670.7

- 5.670.75

- 5.670.8

- 5.670.9

- 5.675.10

- 5.675.100

- 5.675.11

- 5.675.12

- 5.675.14

- 5.675.16

- 5.675.20

- 5.675.25

- 5.675.32

- 5.675.4

- 5.675.50

- 5.675.6

- 5.675.60

- 5.675.7

- 5.675.75

- 5.675.8

- 5.675.9

- 5.690.10

- 5.690.100

- 5.690.11

- 5.690.12

- 5.690.14

- 5.690.16

- 5.690.20

- 5.690.25

- 5.690.32

- 5.690.4

- 5.690.40

- 5.690.50

- 5.690.6

- 5.690.60

- 5.690.7

- 5.690.75

- 5.690.8

- 5.690.9

- 5.700.10

- 5.700.100

- 5.700.11

- 5.700.12

- 5.700.14

- 5.700.16

- 5.700.20

- 5.700.25

- 5.700.32

- 5.700.4

- 5.700.50

- 5.700.6

- 5.700.60

- 5.700.7

- 5.700.75

- 5.700.8

- 5.700.9

- 5.710.10

- 5.710.100

- 5.710.11

- 5.710.12

- 5.710.14

- 5.710.16

- 5.710.20

- 5.710.25

- 5.710.32

- 5.710.4

- 5.710.50

- 5.710.6

- 5.710.60

- 5.710.7

- 5.710.75

- 5.710.8

- 5.710.9

- 5.720.10

- 5.720.100

- 5.720.11

- 5.720.12

- 5.720.14

- 5.720.16

- 5.720.20

- 5.720.25

- 5.720.32

- 5.720.4

- 5.720.50

- 5.720.6

- 5.720.60

- 5.720.7

- 5.720.75

- 5.720.8

- 5.720.9

- 5.725.10

- 5.725.100

- 5.725.11

- 5.725.12

- 5.725.14

- 5.725.16

- 5.725.20

- 5.725.25

- 5.725.30

- 5.725.32

- 5.725.4

- 5.725.50

- 5.725.6

- 5.725.60

- 5.725.7

- 5.725.75

- 5.725.8

- 5.725.9

- 5.740.10

- 5.740.100

- 5.740.11

- 5.740.12

- 5.740.14

- 5.740.16

- 5.740.20

- 5.740.25

- 5.740.32

- 5.740.50

- 5.740.6

- 5.740.60

- 5.740.7

- 5.740.75

- 5.740.8

- 5.740.9

- 5.750.10

- 5.750.100

- 5.750.11

- 5.750.12

- 5.750.14

- 5.750.16

- 5.750.20

- 5.750.25

- 5.750.32

- 5.750.4

- 5.750.50

- 5.750.6

- 5.750.60

- 5.750.7

- 5.750.75

- 5.750.8

- 5.750.9

- 5.765.10

- 5.765.100

- 5.765.11

- 5.765.110

- 5.765.12

- 5.765.14

- 5.765.16

- 5.765.20

- 5.765.25

- 5.765.30

- 5.765.32

- 5.765.4

- 5.765.50

- 5.765.6

- 5.765.60

- 5.765.7

- 5.765.75

- 5.765.8

- 5.765.9

- 5.780.10

- 5.780.100

- 5.780.11

- 5.780.12

- 5.780.14

- 5.780.150

- 5.780.16

- 5.780.20

- 5.780.25

- 5.780.32

- 5.780.4

- 5.780.50

- 5.780.6

- 5.780.60

- 5.780.7

- 5.780.75

- 5.780.8

- 5.780.9

- 5.800.10

- 5.800.100

- 5.800.11

- 5.800.12

- 5.800.14

- 5.800.16

- 5.800.20

- 5.800.25

- 5.800.30

- 5.800.32

- 5.800.4

- 5.800.50

- 5.800.6

- 5.800.60

- 5.800.7

- 5.800.75

- 5.800.8

- 5.800.9

- 5.815.10

- 5.815.100

- 5.815.11

- 5.815.12

- 5.815.120

- 5.815.125

- 5.815.14

- 5.815.150

- 5.815.16

- 5.815.18

- 5.815.20

- 5.815.25

- 5.815.29

- 5.815.30

- 5.815.32

- 5.815.4

- 5.815.50

- 5.815.6

- 5.815.60

- 5.815.7

- 5.815.75

- 5.815.8

- 5.815.9

- 5.830.10

- 5.830.100

- 5.830.11

- 5.830.12

- 5.830.14

- 5.830.16

- 5.830.20

- 5.830.25

- 5.830.32

- 5.830.4

- 5.830.50

- 5.830.6

- 5.830.60

- 5.830.7

- 5.830.75

- 5.830.8

- 5.830.9

- 5.840.10

- 5.840.100

- 5.840.11

- 5.840.12

- 5.840.14

- 5.840.152

- 5.840.16

- 5.840.20

- 5.840.25

- 5.840.30

- 5.840.32

- 5.840.4

- 5.840.50

- 5.840.6

- 5.840.60

- 5.840.7

- 5.840.75

- 5.840.8

- 5.840.9

- 5.850.10

- 5.850.100

- 5.850.11

- 5.850.12

- 5.850.14

- 5.850.16

- 5.850.20

- 5.850.25

- 5.850.32

- 5.850.4

- 5.850.50

- 5.850.6

- 5.850.60

- 5.850.7

- 5.850.75

- 5.850.8

- 5.850.9

- 5.860.10

- 5.860.100

- 5.860.11

- 5.860.12

- 5.860.14

- 5.860.16

- 5.860.20

- 5.860.25

- 5.860.32

- 5.860.4

- 5.860.50

- 5.860.6

- 5.860.60

- 5.860.7

- 5.860.75

- 5.860.8

- 5.860.9

- 5.885.10

- 5.885.100

- 5.885.11

- 5.885.12

- 5.885.14

- 5.885.16

- 5.885.20

- 5.885.240

- 5.885.25

- 5.885.32

- 5.885.4

- 5.885.50

- 5.885.6

- 5.885.60

- 5.885.7

- 5.885.75

- 5.885.8

- 5.885.9

- 5.900.10

- 5.900.100

- 5.900.11

- 5.900.12

- 5.900.120

- 5.900.124

- 5.900.14

- 5.900.150

- 5.900.16

- 5.900.20

- 5.900.25

- 5.900.300

- 5.900.32

- 5.900.4

- 5.900.50

- 5.900.6

- 5.900.60

- 5.900.7

- 5.900.75

- 5.900.8

- 5.900.9

- 5.920.10

- 5.920.100

- 5.920.11

- 5.920.12

- 5.920.14

- 5.920.145

- 5.920.16

- 5.920.160

- 5.920.20

- 5.920.25

- 5.920.32

- 5.920.4

- 5.920.50

- 5.920.6

- 5.920.60

- 5.920.7

- 5.920.75

- 5.920.8

- 5.920.9

- 5.925.10

- 5.925.100

- 5.925.11

- 5.925.12

- 5.925.14

- 5.925.16

- 5.925.20

- 5.925.25

- 5.925.30

- 5.925.32

- 5.925.4

- 5.925.50

- 5.925.6

- 5.925.60

- 5.925.7

- 5.925.75

- 5.925.8

- 5.925.9

- 5.940.10

- 5.940.100

- 5.940.11

- 5.940.12

- 5.940.124

- 5.940.14

- 5.940.150

- 5.940.16

- 5.940.20

- 5.940.200

- 5.940.25

- 5.940.32

- 5.940.4

- 5.940.50

- 5.940.6

- 5.940.60

- 5.940.7

- 5.940.75

- 5.940.8

- 5.940.9

- 5.990.10

- 5.990.100

- 5.990.11

- 5.990.12

- 5.990.124

- 5.990.14

- 5.990.16

- 5.990.20

- 5.990.25

- 5.990.300

- 5.990.32

- 5.990.4

- 5.990.40

- 5.990.50

- 5.990.6

- 5.990.60

- 5.990.7

- 5.990.75

- 5.990.8

- 5.990.9

- 5D1075.10

- 5D1075.100

- 5D1075.11

- 5D1075.12

- 5D1075.14

- 5D1075.16

- 5D1075.20

- 5D1075.25

- 5D1075.30

- 5D1075.32

- 5D1075.50

- 5D1075.6

- 5D1075.60

- 5D1075.7

- 5D1075.75

- 5D1075.8

- 5D1100.10

- 5D1100.100

- 5D1100.11

- 5D1100.12

- 5D1100.14

- 5D1100.16

- 5D1100.190

- 5D1100.20

- 5D1100.25

- 5D1100.32

- 5D1100.50

- 5D1100.6

- 5D1100.60

- 5D1100.7

- 5D1100.75

- 5D1100.8

- 5D1325.10

- 5D1325.100

- 5D1325.11

- 5D1325.12

- 5D1325.14

- 5D1325.16

- 5D1325.20

- 5D1325.25

- 5D1325.32

- 5D1325.50

- 5D1325.6

- 5D1325.60

- 5D1325.7

- 5D1325.75

- 5D1325.8

- 5D260.10

- 5D260.100

- 5D260.11

- 5D260.12

- 5D260.14

- 5D260.16

- 5D260.20

- 5D260.25

- 5D260.32

- 5D260.50

- 5D260.6

- 5D260.60

- 5D260.7

- 5D260.75

- 5D260.8

- 5D300.10

- 5D300.100

- 5D300.11

- 5D300.12

- 5D300.14

- 5D300.16

- 5D300.20

- 5D300.25

- 5D300.32

- 5D300.50

- 5D300.6

- 5D300.60

- 5D300.7

- 5D300.75

- 5D300.8

- 5D400.10

- 5D400.100

- 5D400.11

- 5D400.12

- 5D400.14

- 5D400.16

- 5D400.20

- 5D400.25

- 5D400.32

- 5D400.50

- 5D400.6

- 5D400.60

- 5D400.7

- 5D400.75

- 5D400.8

- 5D410.10

- 5D410.100

- 5D410.11

- 5D410.12

- 5D410.14

- 5D410.16

- 5D410.20

- 5D410.25

- 5D410.32

- 5D410.50

- 5D410.56

- 5D410.6

- 5D410.60

- 5D410.7

- 5D410.75

- 5D410.8

- 5D460.10

- 5D460.100

- 5D460.11

- 5D460.12

- 5D460.14

- 5D460.16

- 5D460.20

- 5D460.200

- 5D460.25

- 5D460.32

- 5D460.50

- 5D460.6

- 5D460.60

- 5D460.7

- 5D460.75

- 5D460.8

- 5D500.10

- 5D500.100

- 5D500.11

- 5D500.12

- 5D500.14

- 5D500.16

- 5D500.20

- 5D500.25

- 5D500.32

- 5D500.50

- 5D500.6

- 5D500.60

- 5D500.7

- 5D500.75

- 5D500.8

- 5D515.10

- 5D515.100

- 5D515.11

- 5D515.12

- 5D515.14

- 5D515.16

- 5D515.20

- 5D515.200

- 5D515.25

- 5D515.32

- 5D515.50

- 5D515.6

- 5D515.60

- 5D515.7

- 5D515.75

- 5D515.8

- 5D525.10

- 5D525.100

- 5D525.11

- 5D525.12

- 5D525.14

- 5D525.16

- 5D525.20

- 5D525.25

- 5D525.32

- 5D525.50

- 5D525.6

- 5D525.60

- 5D525.7

- 5D525.75

- 5D525.8

- 5D550.10

- 5D550.100

- 5D550.11

- 5D550.12

- 5D550.14

- 5D550.16

- 5D550.20

- 5D550.25

- 5D550.32

- 5D550.50

- 5D550.6

- 5D550.60

- 5D550.7

- 5D550.75

- 5D550.8

- 5D590.10

- 5D590.100

- 5D590.11

- 5D590.12

- 5D590.14

- 5D590.16

- 5D590.20

- 5D590.25

- 5D590.32

- 5D590.50

- 5D590.6

- 5D590.60

- 5D590.7

- 5D590.75

- 5D590.8

- 5D600.10

- 5D600.100

- 5D600.11

- 5D600.12

- 5D600.14

- 5D600.16

- 5D600.20

- 5D600.25

- 5D600.32

- 5D600.50

- 5D600.6

- 5D600.60

- 5D600.7

- 5D600.75

- 5D600.8

- 5D620.10

- 5D620.100

- 5D620.11

- 5D620.12

- 5D620.14

- 5D620.16

- 5D620.20

- 5D620.25

- 5D620.32

- 5D620.50

- 5D620.6

- 5D620.60

- 5D620.7

- 5D620.75

- 5D620.8

- 5D625.10

- 5D625.100

- 5D625.11

- 5D625.12

- 5D625.14

- 5D625.16

- 5D625.20

- 5D625.25

- 5D625.32

- 5D625.50

- 5D625.6

- 5D625.60

- 5D625.7

- 5D625.75

- 5D625.8

- 5D650.10

- 5D650.100

- 5D650.11

- 5D650.12

- 5D650.14

- 5D650.16

- 5D650.20

- 5D650.25

- 5D650.32

- 5D650.50

- 5D650.6

- 5D650.60

- 5D650.7

- 5D650.75

- 5D650.8

- 5D700.10

- 5D700.100

- 5D700.12

- 5D700.14

- 5D700.16

- 5D700.20

- 5D700.25

- 5D700.32

- 5D700.50

- 5D700.6

- 5D700.60

- 5D700.7

- 5D700.75

- 5D700.8

- 5D750.10

- 5D750.100

- 5D750.11

- 5D750.12

- 5D750.14

- 5D750.16

- 5D750.20

- 5D750.25

- 5D750.255

- 5D750.32

- 5D750.50

- 5D750.6

- 5D750.60

- 5D750.7

- 5D750.75

- 5D750.8

- 5D775.10

- 5D775.100

- 5D775.11

- 5D775.12

- 5D775.14

- 5D775.16

- 5D775.20

- 5D775.25

- 5D775.32

- 5D775.50

- 5D775.6

- 5D775.60

- 5D775.7

- 5D775.75

- 5D775.8

- 5D800.10

- 5D800.100

- 5D800.11

- 5D800.12

- 5D800.14

- 5D800.16

- 5D800.20

- 5D800.25

- 5D800.32

- 5D800.50

- 5D800.6

- 5D800.60

- 5D800.7

- 5D800.75

- 5D800.8

- 5D815.10

- 5D815.100

- 5D815.11

- 5D815.12

- 5D815.14

- 5D815.16

- 5D815.20

- 5D815.25

- 5D815.30

- 5D815.32

- 5D815.50

- 5D815.6

- 5D815.60

- 5D815.7

- 5D815.75

- 5D815.8

- 5D815.9

- 5D860.10

- 5D860.100

- 5D860.11

- 5D860.12

- 5D860.14

- 5D860.16

- 5D860.20

- 5D860.25

- 5D860.32

- 5D860.50

- 5D860.6

- 5D860.60

- 5D860.7

- 5D860.75

- 5D860.8

- 5D900.10

- 5D900.100

- 5D900.11

- 5D900.12

- 5D900.14

- 5D900.16

- 5D900.20

- 5D900.25

- 5D900.32

- 5D900.50

- 5D900.6

- 5D900.60

- 5D900.7

- 5D900.75

- 5D900.8

- 5D940.10

- 5D940.100

- 5D940.11

- 5D940.12

- 5D940.14

- 5D940.16

- 5D940.20

- 5D940.25

- 5D940.32

- 5D940.50

- 5D940.6

- 5D940.60

- 5D940.7

- 5D940.75

- 5D940.8

- 5K1380.12

- 5K1380.135

- 5K1380.170

- 5K1380.25

- 5K1380.270

- 5K1380.6

- 5K150.10

- 5K150.25

- 5K180.10

- 5K200.10

- 5K200.12

- 5K210.10

- 5K210.8

- 5K295.10

- 5K295.100

- 5K295.11

- 5K295.12

- 5K295.14

- 5K295.16

- 5K295.32

- 5K295.4

- 5K295.50

- 5K295.6

- 5K295.60

- 5K295.7

- 5K295.75

- 5K295.8

- 5K295.9

- 5K295K20

- 5K295K25

- 5K340.16

- 5K340.25

- 5K500.25

- 5K525.10

- 5K525.12

- 5K525.16

- 5K525.25

- 5K525.6

- 5K575.10

- 5K575.12

- 5K575.20

- 5K575.25

- 5K650.10

- 5K650.15

- 5K650.16

- 5K650.25

- 5K650.32

- 5K720.25

- 5K750.20

- 5K750.25

- 5K765.10

- 5K765.100

- 5K765.11

- 5K765.12

- 5K765.14

- 5K765.16

- 5K765.20

- 5K765.25

- 5K765.32

- 5K765.4

- 5K765.50

- 5K765.6

- 5K765.60

- 5K765.7

- 5K765.75

- 5K765.8

- 5K765.9

- 5K830.10

- 5K840.10

- 5K840.100

- 5K840.11

- 5K840.12

- 5K840.14

- 5K840.16

- 5K840.20

- 5K840.25

- 5K840.32

- 5K840.4

- 5K840.50

- 5K840.6

- 5K840.60

- 5K840.7

- 5K840.75

- 5K840.8

- 5K840.9

- 5K900.12

- 5K900.16

- 5K900.50

- 10.1000.10

- 10.1000.100

- 10.1000.11

- 10.1000.12

- 10.1000.14

- 10.1000.16

- 10.1000.20

- 10.1000.25

- 10.1000.32

- 10.1000.50

- 10.1000.6

- 10.1000.60

- 10.1000.7

- 10.1000.75

- 10.1000.8

- 10.1010.10

- 10.1010.100

- 10.1010.11

- 10.1010.12

- 10.1010.14

- 10.1010.16

- 10.1010.20

- 10.1010.25

- 10.1010.30

- 10.1010.32

- 10.1010.50

- 10.1010.6

- 10.1010.60

- 10.1010.7

- 10.1010.75

- 10.1010.8

- 10.1050.10

- 10.1050.100

- 10.1050.11

- 10.1050.12

- 10.1050.14

- 10.1050.16

- 10.1050.20

- 10.1050.25

- 10.1050.32

- 10.1050.50

- 10.1050.6

- 10.1050.60

- 10.1050.7

- 10.1050.75

- 10.1050.8

- 10.1080.10

- 10.1080.100

- 10.1080.11

- 10.1080.12

- 10.1080.125

- 10.1080.14

- 10.1080.16

- 10.1080.20

- 10.1080.200

- 10.1080.25

- 10.1080.30

- 10.1080.32

- 10.1080.35

- 10.1080.50

- 10.1080.6

- 10.1080.60

- 10.1080.7

- 10.1080.75

- 10.1080.8

- 10.1100.10

- 10.1100.100

- 10.1100.11

- 10.1100.12

- 10.1100.14

- 10.1100.16

- 10.1100.20

- 10.1100.25

- 10.1100.32

- 10.1100.50

- 10.1100.6

- 10.1100.60

- 10.1100.7

- 10.1100.75

- 10.1100.8

- 10.1110.10

- 10.1110.100

- 10.1110.11

- 10.1110.12

- 10.1110.14

- 10.1110.16

- 10.1110.20

- 10.1110.25

- 10.1110.32

- 10.1110.35

- 10.1110.50

- 10.1110.6

- 10.1110.60

- 10.1110.7

- 10.1110.75

- 10.1110.8

- 10.1140.10

- 10.1140.100

- 10.1140.11

- 10.1140.12

- 10.1140.14

- 10.1140.150

- 10.1140.16

- 10.1140.20

- 10.1140.25

- 10.1140.32

- 10.1140.50

- 10.1140.6

- 10.1140.60

- 10.1140.7

- 10.1140.75

- 10.1140.8

- 10.1150.10

- 10.1150.100

- 10.1150.11

- 10.1150.12

- 10.1150.120

- 10.1150.13

- 10.1150.14

- 10.1150.16

- 10.1150.20

- 10.1150.25

- 10.1150.275

- 10.1150.32

- 10.1150.50

- 10.1150.6

- 10.1150.60

- 10.1150.7

- 10.1150.75

- 10.1150.8

- 10.1160.10

- 10.1160.100

- 10.1160.11

- 10.1160.12

- 10.1160.14

- 10.1160.16

- 10.1160.20

- 10.1160.25

- 10.1160.32

- 10.1160.50

- 10.1160.6

- 10.1160.60

- 10.1160.7

- 10.1160.75

- 10.1160.8

- 10.1200.10

- 10.1200.100

- 10.1200.11

- 10.1200.12

- 10.1200.14

- 10.1200.16

- 10.1200.20

- 10.1200.25

- 10.1200.32

- 10.1200.50

- 10.1200.6

- 10.1200.60

- 10.1200.7

- 10.1200.75

- 10.1200.8

- 10.1210.10

- 10.1210.100

- 10.1210.11

- 10.1210.12

- 10.1210.14

- 10.1210.140

- 10.1210.15

- 10.1210.16

- 10.1210.20

- 10.1210.25

- 10.1210.30

- 10.1210.32

- 10.1210.50

- 10.1210.6

- 10.1210.60

- 10.1210.7

- 10.1210.75

- 10.1210.8

- 10.1240.10

- 10.1240.100

- 10.1240.11

- 10.1240.12

- 10.1240.14

- 10.1240.16

- 10.1240.20

- 10.1240.25

- 10.1240.32

- 10.1240.50

- 10.1240.6

- 10.1240.60

- 10.1240.7

- 10.1240.75

- 10.1240.8

- 10.1250.10

- 10.1250.100

- 10.1250.11

- 10.1250.12

- 10.1250.14

- 10.1250.16

- 10.1250.20

- 10.1250.200

- 10.1250.25

- 10.1250.30

- 10.1250.32

- 10.1250.40

- 10.1250.50

- 10.1250.6

- 10.1250.60

- 10.1250.7

- 10.1250.75

- 10.1250.8

- 10.1260.10

- 10.1260.100

- 10.1260.11

- 10.1260.12

- 10.1260.14

- 10.1260.16

- 10.1260.20

- 10.1260.25

- 10.1260.32

- 10.1260.50

- 10.1260.6

- 10.1260.60

- 10.1260.7

- 10.1260.75

- 10.1260.8

- 10.1280.10

- 10.1280.100

- 10.1280.11

- 10.1280.12

- 10.1280.14

- 10.1280.16

- 10.1280.20

- 10.1280.25

- 10.1280.32

- 10.1280.50

- 10.1280.6

- 10.1280.60

- 10.1280.7

- 10.1280.75

- 10.1280.8

- 10.1300.10

- 10.1300.100

- 10.1300.11

- 10.1300.12

- 10.1300.14

- 10.1300.16

- 10.1300.20

- 10.1300.25

- 10.1300.30

- 10.1300.32

- 10.1300.50

- 10.1300.6

- 10.1300.60

- 10.1300.7

- 10.1300.75

- 10.1300.8

- 10.1320.10

- 10.1320.100

- 10.1320.11

- 10.1320.12

- 10.1320.120

- 10.1320.14

- 10.1320.140

- 10.1320.16

- 10.1320.20

- 10.1320.25

- 10.1320.30

- 10.1320.32

- 10.1320.50

- 10.1320.6

- 10.1320.60

- 10.1320.7

- 10.1320.75

- 10.1320.8

- 10.1330.10

- 10.1330.100

- 10.1330.11

- 10.1330.12

- 10.1330.14

- 10.1330.16

- 10.1330.20

- 10.1330.25

- 10.1330.32

- 10.1330.50

- 10.1330.6

- 10.1330.60

- 10.1330.7

- 10.1330.75

- 10.1330.8

- 10.1350.10

- 10.1350.100

- 10.1350.11

- 10.1350.12

- 10.1350.14

- 10.1350.16

- 10.1350.20

- 10.1350.25

- 10.1350.30

- 10.1350.32

- 10.1350.50

- 10.1350.6

- 10.1350.60

- 10.1350.7

- 10.1350.75

- 10.1350.8

- 10.1360.10

- 10.1360.100

- 10.1360.11

- 10.1360.12

- 10.1360.14

- 10.1360.16

- 10.1360.20

- 10.1360.25

- 10.1360.32

- 10.1360.50

- 10.1360.6

- 10.1360.60

- 10.1360.7

- 10.1360.75

- 10.1360.8

- 10.1390.10

- 10.1390.100

- 10.1390.11

- 10.1390.12

- 10.1390.14

- 10.1390.16

- 10.1390.20

- 10.1390.25

- 10.1390.30

- 10.1390.32

- 10.1390.50

- 10.1390.6

- 10.1390.60